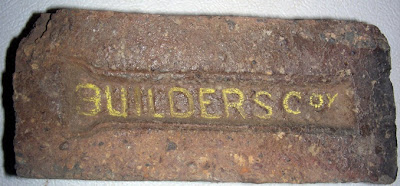

Trading Name

|

Glen Iris Bricks

|

Business Name

|

The Glen Iris Brick Tile and Terra Cotta Co Pty Ltd

|

Years of Operation

|

1912 to 1972

|

Company Number

|

ACN 004 063 843

|

Address

|

Stamford Road to the West and Estelle Street to the North

|

Council Lot No.

|

|

Coordinates

|

-37.892991, 145.101221

|

Current Use

|

Public Open Space, Sporting ground

|

The

Glen Iris Brick Tile and Terra Cotta Co Pty Ltd began as a

response to the Co-operative by disgruntled builders. Office holders were Benjamin

J Davis Chairman, Isaac Fenton Secretary and Charles Stacey Manager. The company commenced on the Oakleigh

site on the 5th of March 1912.

In April 1912, an agreement was entered into by the Glen Iris Brick and

Tile Company for the lease on a portion of land at Thornbury acquired by the

late Sir Thomas Bent for the purpose of brickmaking. Under the provisions of the contract, the company had control of

of land comprising about 30 acres in all, for a long term. They agreed to pay £150 per annum and to

supply the brick requirements of the Government for seven years at 31/- per

thousand.

As the Government had only paid £5,000 for the whole area, the deal with

the company, (bricks will be supplied for all state works at 7/- per thousand

less than the current going rate) was regarded by the authorities as highly

satisfactory. No selling price to the

public was included in the agreement.

This would depend on circumstances, but the company has undertaken not to enter into any agreement with any

other manufacturer of bricks in order to fix prices or regulate output. It proposes to conduct its business on

independent lines.

Everything was in

readiness on the part of the company to start operations at once. Up-to-date equipment had been manufactured

for them by Messrs Anderson and Sons of Richmond who made milling machines and

the power would be supplied by a suction gas engine manufactured by Kynoch Ltd

of Birmingham, a munitions company still in existence, that had taken over the

Forward Engineering Co that made the gas engines. A Hoffman kiln and two drying chambers were to be erected and it

was intended that everything in connection with the whole plant would be the

most modern design.

It was the intention of the company at first to establish works in the

neighbourhood of Glen Iris, hence the name.

Some 40 acres of land was secured at Camberwell on one side of Gardiners

Creek and 6 acres in Malvern on the other side of the creek. The intention of the company, the capital of

which consists of 20,000 shares of £1 each was to build its brick making plant

at the site of the clay deposit in Camberwell and to erect its kiln on the

Malvern site.

It was further proposed to cut up a portion of the area for workmen’s

homes and to enable the land to be purchased on reasonable terms. Anticipating that there would be no

obstacles to an enterprise that it was thought would give employment to about

150 men. The brick making plant

intended for Camberwell be placed on the Thornbury land was ordered and the

suction gas engine was arranged for.

The Camberwell Council however took action that prevented the company

from starting operations there and caused the directors to turn their eyes in

other directions. A by-law of the

council provides that neither quarrying nor blasting shall be allowed in

certain areas. This particular land

came within the prescribed area and the council decided that the by-law should

be enforced in regard to it.

Councillor Rooks, was a member

of the Camberwell Council, and also a shareholder in the

City Brick Company. During

his term of office as Mayor of Camberwell, he had a

by-law framed stopping quarrying in the municipality, and thereby gave

a monopoly to the Camberwell and Auburn Brick Companies,

that were operating in the city at the time and not affected by the new bv-law. Blocked on both sides, the company put its case before the Premier.

The brickworks from inside the pit.

Photo 's courtesy of H.Gobbi, Taking its Place: a History of Oakleigh

An offer was made

to him that if he gave his support, the company would supply bricks at a

reduced cost to the Government. The

Premier, Mr Murray suggested the erection of a kiln on the Thornbury

Estate. At a saving of 11/- per 1,000 during a term

of 21 years (the length of time

the company was to hold its lease), the Government would save £5,250 per annum, and £110,250 over the whole term. He

estimated that the income to the Government

for the lease of the land, at £12.10/ per acre in 21 years would have been £3,150.

They were located on St Georges

Rd in Thornbury, bordered by Miller St to the North, Watt St to the South and

the railway line to the East. The site had first been promoted as a possible

state brickworks in 1905 by then Victorian Premier, Sir Thomas Bent. Bent was

unimpressed with the control that Melbourne’s major brickworks exorcised over

the price of bricks and was keen to force a better deal for the

government.

The government had bought 30

acres of land in Thornbury in December 1904.

Bent was aiming to bluff the brick company cartel to lower their prices

from 40 shillings per thousand. After

going as far as clearing the land and putting up buildings on the site, the

brick companies conceded and dropped their price to 38 shillings per thousand.

Development of the site was halted. However the fallout would continue to

reverberate.

In mid 1905 the Auditor General had queried the purchase of the land, as the

funds had been set aside for the construction and maintenance of workers’ homes

in the area. Bent was later found to have misled parliament when he stated that

the land had been bought for this purpose.

This, along with some other questionable land dealings, would bring

about the downfall of Bent’s government in 1908.

By 1912 the land, which had been the subject of rumour ever since the

brickworks were originally planned, had been subdivided and looked set to be

sold. Then, suddenly, in April of that

year, the Murray Government, who had launched the original royal commission in

opposition in 1905, announced that they had let a large part of the land in

Thornbury to the Glen Iris Brick Company.

They began operations in 1912,

and initially endured hostile press from the Leader and protests by local

residents. But they stayed, and the government, having signed a long-term

contract with the state government to supply bricks for thirty-one shillings

per thousand, were thrilled with the situation.

Glen Iris Brickworks, Oakleigh 1931

Though the brickworks has long ceased operation, the land remained crown until

the late 1970’s when the Northcote Council suggested that the Aborigines

Advancement League pursue developing the land for a new home. Pastor Sir Douglas Nicholls had originally

founded the League in 1958 with headquarters in Cunningham St. In 1981 the Victorian Government ceded two acres

of the old quarry land to the league as well as contributing part of the $750,000

needed to fund the building. This was the first freehold land granted to

indigenous people in Victoria. The rest of the site is now devoted to the Sir

Douglas Nicholls Oval and some housing blocks.

Under the terms of

the original 1912 agreement, should the company combine with any other works or break any clause of the

undertaking, the whole of the company's works would

revert to the Crown.

The kilns anyway, would go to the Government at the end of 21 years. It was

believed that pressure had been brought to bear on the councils to stop the erection of the Glen Iris Company’s works

Brickworks 1945

The Glen Iris Company has been making bricks on a small scale for about

two months. As some difficulty in

obtaining bricks for the kiln that was intended to build at Camberwell was

feared, a small hand plant and kiln was placed on land at Oakleigh in order

that requirements could be met. These

bricks would now be used at Thornbury.

As part of the deal, a railway siding was built to help transport their

bricks. There is a conspiracy theory

that the State Brick Works was allowed to fail because of the Government deal

with Glen Iris Brick Co and their ability to get bricks to Wonthaggi more

cheaply than the locally made product.

Originally their capacity was

four million bricks per-annum but in 1936, new kilns were opened increasing

capacity by eight million bricks to twelve million per annum. Boral Bricks

purchased Glen Iris in 1970. By 1975

they had acquired almost 95% of the shares in the company. Takeover was completed on the 4th

of February 1976 when Glen Iris Consolidated Industries was de-listed by the

Australian Stock Exchange. Nothing

remains on site except the remains of the brick pit that was filled as a

Council garbage dump and is now a sports ground.

Glen

Iris Brickworks, Stamford Road, Oakleigh 1968

Glen Iris Brickworks, Stamford Road, Oakleigh 1972

.jpg)